After trying to knit with my predrafted hankies on 2.5 mm needles I decided to give them a bit of twist. Having done that, I decided to ply them as well…. Too fiddly otherwise, snagging on the join of my circulars, just plain ARGH. I think if I’d drafted them thicker it might have been easier, maybe I just suffer from old lady eyes….

One mitt done, weighing in at 9.6 g. I have a total of 44 g of silk judged from various pattern, so apparently silk weighs nothing compared to wool. I’d originally wanted them really thin, which obviously isn’t happening on 3.5 mm, so I ended up not making individual fingers, not wanting too much material between each. Dunno what I’ll do with the other half of the yarn. Matching earmuffs? LOL. Or just a nicer pair of mittens…

I made up the pattern as I went along, and being my first glove ever, I see lots of room for improvement, but they’ll do their job. When I tried them on before casting off, the 3-finger part seemed longer unfortunately, I would have liked them to extend to the last(first) joint. But I’ve already woven in ends, tough luck.

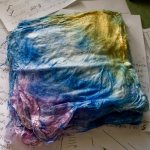

I’m as yet undecided whether I like to work with hankies or not. I like silk and I don’t mind the rustic look that you get, but I think it’s really hard on the fingers to pull them open, as well as quite boring compared to spinning. I’ve got about 300 g left of them, they don’t cost extra rent I suppose, so they can either sit there or I could dye them and hope someone else will care for them more than I do. I have plenty of silk top to work with instead!

â Leave a Comment

Fingerløs

Første forsøg med vantestrikning, det gik ikke helt som planlagt, men jeg er ok tilfreds alligevel. Jeg brugte meget mindre garn end jeg havde regnet med, den første vante vejer kun 9,6 g og jeg har 44 g i alt. Den sidder endda ret løst, selvom jeg troede jeg havde strikket den for lille, da silke jo strækker sig. Jeg kan så konstatere, at det strækker sig MEGET!

Jeg ved ikke helt hvad jeg synes om hankies, jeg synes det er hårdt at trække dem ud til tråd. Men jeg har købt 300 g, så jeg må vel hellere få dem farvet og finde på et eller andet.